SemiAccurate will depart from our usual chip reporting to bring you a take of abject engineering stupidity. This time the stupid concerns bicycles and comes courtesy of Trek.

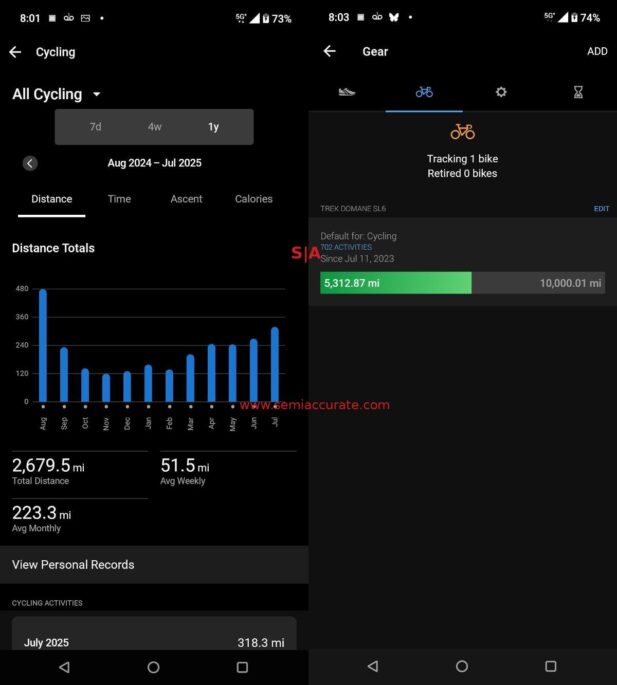

For those readers who don’t know me, I am a big biker, about 2500 miles a year give or take a few hundred. About two years ago, July 11, 2023 to be exact, I replaced my worn out no-name bike with a Trek Domane SL 6 Gen 4 bike. From the beginning it was a turd, problems you would return a $79 Costco bike for were common. The seat post creaked and constantly sunk. The electronic shifter just stopped in the middle of a ride. Twice. And more.

Mileage stats from my Garmin (bleargh) App

If it wasn’t for the truly excellent service at my local shop, I would have returned it. That said it was out of service for many weeks while Trek dithered on what to do and parts were ordered. Like the finest of 1960s British sports cars, the bike has been quite reliable for the past year or so. Again like the cars, this is mainly because half the parts it came with have been replaced by properly engineered replacements. Unfortunately for the bike, that last bit is just almost true.

The bike died almost exactly here

The problem happened last Friday on a long ride on a trail about a mile from the nearest exit. Scenic but hardly the spot where you want this kind of thing to happen. I was riding down a smooth paved trail as always when I heard a snap. I thought I ran over something and coasted along waiting for the inevitable face full of tire sealant compound which never came. As soon as I started pedaling again, the bike moved under me, the frame was no longer carbon, it was jello.

The seat post visibly wobbled but didn’t sink, the exact opposite of when I bought it. The mechanism was visibly intact and did hold the seat tight in both directions so I made the call to bike home. Slowly. Off the seat. The frame lost enough torsional rigidity to make this a very interesting and unique feeling experience but slow and steady was the only way to get home. About 100 yards later I hear some more noises as the parts the bike shed hit the trail.

Why did this happen? Trek’s abjectly stupid engineering choices. Why make things simple, effective, and cheap when you can do overly complex mechanisms that don’t really work, cost a lot, and are rife with product quality issues? Lets look at what Trek did and what they SHOULD have done in this case. It is a tale of corporate stupidity made real by engineering idiocy.

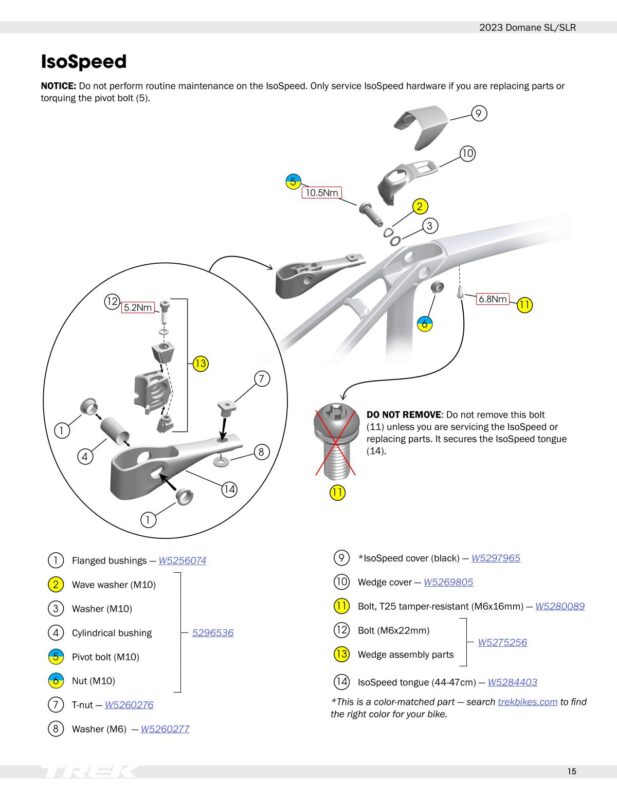

The Trek Domane SL 6 Gen 4 Service Manual Page 16

To start off, all of the drawings for this are from the Trek Domane SL 6 Gen 4 service manual found here, page 16. If you look at the drawing above, it is for something Trek calls IsoSpeed, a mechanism to ostensibly designed to make the ride smoother. Whether it does or not is an open question, the ride is unquestionably smoother than my last bike but I attribute that to 75PSI tires vs 115PSI on the old bike. In any case it is a very complex mechanism that puts the seatpost on a spring. Sort of.

If you look at the teardrop shaped bit that is enlarged in the circle, that is the IsoSpeed mechanism. It bolts to the frame at the front and the seat post goes though the back. Parts 6, 7, and 8 hold things to the frame itself. The seatpost retention mechanism that failed multiple times when I first got the bike are parts 12 and 13. This mechanism is both complex, expensive, and dumb. It is basically two wedges that you force together with a screw. They slide sideways and apply pressure to the seatpost and the friction, and some carbon holding compound, keeps the seat post in place. On paper this is a good idea, reality showed the opposite is true.

From there, a hollow metal pin goes through the center of the IsoSpeed mechanism just below the seat post retaining wedge mechanism and a bit ahead of the post itself. This is what supports the seat post and the rider, it is a spring, damper, and pivot. Parts 2, 3, 5, and 6 are the pin, 1 and 4 are the tube it resides in. The whole mechanism is covered by an ostensibly weatherproofing rubber gasket, part 10, and a plastic cover with two magnets in the ‘wings’ to hold it on, part 9. So far so complex.

Bad design and bad material

Now lets get into the stupid engineering. As you can see from the above, the pin isn’t fit for purpose. It is a cheap alloy that doesn’t take kindly to repeated small stresses. Unfortunately that is what the whole mechanism was designed to deal with, every bump and expansion joint you hit on the bike puts a lot of weight on that pin, assuming you are on the seat. The flex of that pin ostensibly absorbs some of the shock of high frequency impacts, at least as far as I can figure out. The ends of the pin have at tapered edge which means stresses along a second axis stretch the spring as well, but this isn’t shown in the diagrams. Sigh.

The pin broke without warning, that was the snap I mentioned. The alloy they used was cheap, very cheap, so cheap that for the first hour or so that I was looking at it, I thought it was plastic. You can see the posts I made on Bluesky at the time. I only figured out that it was metal when the magnets in the wing, part 10, stuck to it. The parts that littered the bike path were parts of the broken pin, the wing, the magnets, and the washers. The long part of the pin stayed on the bike but not in place, more on that in a bit.

I can’t see my house from here

Why is this incomprehensibly stupid engineering? Let me list the ways. No really, I am going to go through most of them, feel free to email me if I missed any. The first and most obvious is to make a part meant to take repeated impacts, and to damp them, out of an insufficiently strong alloy and not put enough in. I get the hollow part, you want it to flex a bit to absorb shock, think anti-roll bars in cars. This can be tuned up or down but whatever you do, you need to make it strong enough. Trek obviously didn’t. Then there is the forces along a second axis which likely didn’t help the situation.

Then there is the seatpost retention part which failed repeatedly multiple times when the bike was new. While I can’t say if the fixed parts differ from the original, I have my suspicions. In any case a normal bike has a ring clamp that holds the seat in place and offers infinite adjustments. City bikes and exercise bikes tend to have a pin that goes into holes in the seat, easy to use, impossible to under-tighten, and rather robust. Both mechanisms have ups and downs, have been common for decades, and just work.

Trek took a different path with their IsoSpeed. The seatpost is not standard, IE not round, think a fat teardrop with the taper at the rear. This is both good and bad, the good being that you don’t have to fiddle with the angle of the seat, it always is aligned right. The down side is that you can’t get an off the shelf seat post, Trek only, and you can’t use a ring clamp on it.

So what do you do when you can’t use a simple, effective, and cheap ring clamp on the seat post? You design a complex, expensive, failure-prone mechanism like the wedge system in the Trek IsoSpeed. This is dumb, really really dumb, an avoidable error. Before you say that a ring clamp on a carbon seatpost is a bad idea, you would be wrong for two reasons. First the seatpost in question is metal, since the bike is in the shop I can’t say which metal, just not carbon. The second issue is that the last bike I had did have a round carbon seatpost held in place with a ring clamp. It worked great, all you needed was a little carbon grit/grip compound and all was good. Trek wins on avoiding annoying alignment foibles, the obvious way wins on cost, ease of use, and complexity.

Then you have to ask the obvious question of why Trek made the IsoSpeed mechanism in the first place. Sure bad choices led to more bad choices on the seat post retention part, but the suspension bit is a head scratcher. Does it damp high frequency shocks that come through the frame? I am sure trek has data that says it does, I am not questioning that bit. The first part I am questioning is that the pin in the tube has rotational freedom on one side but is fixed on the other so it can’t rotate. It will move a bit when the IsoSpeed tongue, part 14, the teardrop bit, flexes. A properly designed carbon fiber layup would be much better in every way, and simpler more on this later. Damping the impacts with a material meant to do so is much smarter idea and would reduce the part count a lot. Again, the path Trek took is just dumb.

If you take on face value that the IsoSpeed does damp these impacts and my view that the lower pressure tires did orders of magnitude more is wrong, then there is still another problem. The IsoSpeed mechanism only damps shocks that come through your behind, admittedly a good thing. Your hands on the handlebar and your feet on the pedals do not benefit from this mechanism. It is complex, failure-prone, and expensive but it keeps the seat properly aligned so, yeah no, it is shit.

So why do I harp on about stupid engineering? All of this could be avoided with two easy and cheap changes. First make a round seat post with a ring clamp, better in every way but alignment. Then put a scribe mark on the post and the clamp so you can align things by eye. Problems solved, cost saved, and complexity vastly reduced.

That however does nothing about high frequency impacts. These can be mitigated, likely much better, by means of a thin layer of gel or memory foam on the seat itself. IsoSpeed only shields your (euphemism for a donkey) so why not do it directly? Cheaper and can be tuned to be much more effective but Trek took the other route. Idiots.

Then comes the ‘wing’, part 9. This fiddly piece of plastic has a tab on the back end and the two circles on the inside clip on to the bolt, parts 5 and 6. There are two magnets to in those circles held on by glue, and held is a bit of a stretch. The plastic itself is rigid enough to hold the wing in place by itself without the magnets. How do I know? Both magnets fell off within weeks of me owning the bike. They add weight, cost, and have a 100% failure record, sample quantity 2. Why Trek, why? Bad engineering there once again.

Moving on to the Wedge Cover, part 10. It is a rubber gasket meant to weatherproof this whole Rube Goldberg system Trek designed. The problem with it is that seemingly weeks into ownership it went from rubber to something at rivals the strength of the broken pin. It is hard, and I mean so hard that it is nearly impossible to get it to sit in place because it is so stiff. Moving the seatpost requires far more work because of this material, something that is annoying but livable. Again Trek made really bad material choices.

Carbon doesn’t like gouges

The last bit is likely the most problematic and it involves the bit of broken pin that didn’t make a jump for freedom on the trail. That part, either 5 or 6 (with part of 5 attached), stayed in and was likely why the bike wobbled like jello when I pedaled. In the 100 or so yards it took me to figure out what happened and stop when the parts shed, that bolt wiggled around a bit. And gouged the carbon frame. Deeply.

The picture doesn’t show it well but the chunk is several layers in well past the paint. You can feel the end of the fibers sticking up. If you know anything about carbon fiber, you know why this is deadly. The place it happened is probably the second highest stress bit of the bike, the first being the area around the crank. It is directly in the load path for the shock the IsoSpeed is meant to damp too. This gouge will be fatal to the frame, it is a matter of if not when. The only question I have now is what excuse Trek will use to deny the warranty, anyone want to start a poll?

So in the end we have shit engineering on Trek’s part. Things that may pass on a cheap no-name bike do not pass on a $5000 high end bike. The overly complex engineering for no reason coupled to flat our wrong material choices are only worsened by serious quality control issues at Trek. Bear in mind that the problems listed above are only SOME of the ones that affected this bike from the factory, I haven’t even gotten into the rims and tires. Or the painful documentation. Or… or… you get the idea. The only bright spot here is the really great service from my local dealer who I am not mentioning so unwarranted grief doesn’t fall on their head. How did Trek get this dumb? How did they get this bad?

They can do it the right way, see?

If you are now thinking why Trek doesn’t know better, they actually do. If you look at the Madone series bikes pictured above, they do things differently. The shocks are absorbed by the shape of the frame and the materials used. The bottom of the seatpost area sits on a carbon extension of the top bar. Materials and layup choices mean that bit is a spring that serves the function of the IsoSpeed debacle with zero parts, and probably does it better. If you want the details, grab the service manual here, page 18.

The seatpost is held in place by a clip and a screw, two cheap parts instead of a complex badly designed, fiddly mechanism in the Domane series. Given the cost of these bikes, owners are not going to take lightly to multiple failures and quality control issues that plague lesser bikes. That said I didn’t enjoy the crap quality that Trek put out either but on the Madone line they seem to have avoided the engineering flaws if not the material choice issues. Trek could have done things worse but it is a struggle for me to see how.S|A

Updated July 23, 2025 @ 9:45am – Trek did the right thing, sort of. Between the time this was written and posted, Trek notified the shop that the frame will be replaced. That is the good news. The bad news is that I picked the bike I did because it is not flashy or hideous like several similar models. Shiny gets stolen more often too.

Trek says the black frame I have/had is no longer available, my choices are blue and white. The blue isn’t too painful but that is backordered for several weeks. The grey is in stock and it looks like crap. In just over a week I should have my bike back with a new frame in grey that looks like crap. *SIGH*